Share

DQ70BZ01-YM Oil Top Drive System

② Silent and environmentally friendly: The gearless reducer and lubrication oil pump operate with low noise; it also uses closed water cooling and hydraulic station lower placement technology, ensuring that the working noise does not exceed 50 decibels, significantly improving the working environment for workers.

③ Completely explosion-proof: The main motor of the top drive uses closed water cooling technology, and the main motor is sealed inside the top drive body, achieving a truly complete explosion-proof function.

If our products meet your current needs, please leave us a message!

View similar products

Keyword List

- Product Description

-

Product Parameters

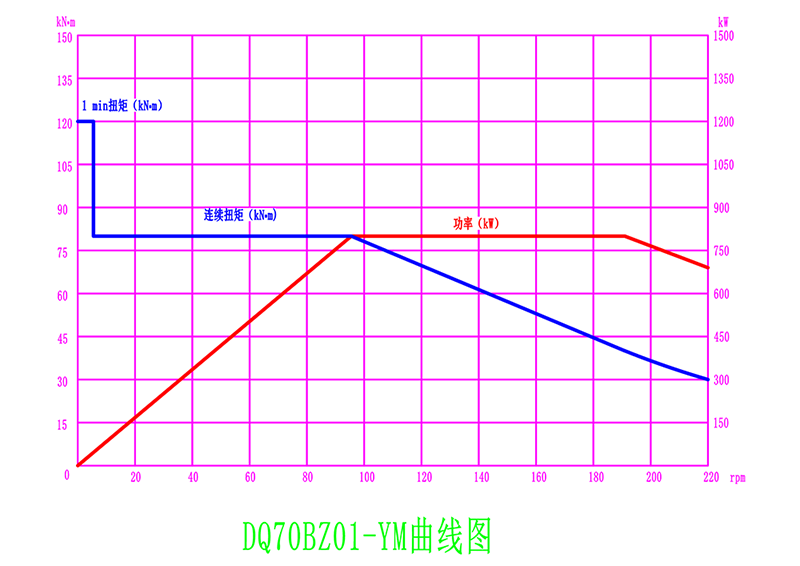

Drive Mode AC Variable Frequency (AC VFD) Nominal Drilling Depth (Φ114mm Drill Rod) 7000m Rated Load 4500kN Power Supply 600VAC/50Hz (Optional 60Hz) Rated Power of Main Motor 800kW (continuous) Torque of Cobalt Well 80kN·m Maximum Uncoupling Torque 120kN·m Spindle Speed Range 0~220r/min Back Clamp Holding Drill Rod Range 86mm~216mm Mud Channel Ф75mm Mud Channel Circulation Pressure 52MPa Upper (Remote Control) 6 5/8" API REG 70MPa Lower (Manual) 6 5/8" API REG 70MPa Hydraulic System Working Pressure 14MPa Working Height 7.1m Main Body Weight 19.5t Ambient Temperature -20℃~55℃ (Optional -45℃~55℃)

① High Efficiency and Energy Saving: The top drive is highly efficient and energy-saving, making it very suitable for the future green and low-carbon development direction of drilling equipment.

② Silent and Environmentally Friendly: The noise from the gearless gearbox and lubrication pump is minimized; it also uses closed water cooling and hydraulic station lower placement technology, with working noise not exceeding 50 decibels, significantly improving the working environment for workers.

③ Completely Explosion-Proof: The main motor of the top drive uses closed water cooling technology, and the main motor is sealed inside the top drive body, achieving true complete explosion-proof functionality.

④ Reliable Performance: The use of electric direct drive technology aims to simplify the internal structure of the top drive housing, avoiding major repairs due to small gear or bearing failures, maximizing the reliability and continuous operation capability of the top drive.

⑤ Convenient Maintenance: Traditional mechanical top drive gear meshing generates metal debris that can contaminate the lubrication oil; the DQZ series top drive uses a gearless reduction mechanism with oil immersion lubrication, effectively extending the service life of the lubrication oil and reducing the frequency of oil changes.

⑥ Precise Control: When the top drive is performing directional inclination or after activating the torque swing reduction function, it requires precise control of the spindle rotation angle and direction.

DQ70BZ01-YM Oil Top Drive System

② Silent and environmentally friendly: The gearless reducer and lubrication oil pump operate with low noise; it also uses closed water cooling and hydraulic station lower placement technology, ensuring that the working noise does not exceed 50 decibels, significantly improving the working environment for workers.

③ Completely explosion-proof: The main motor of the top drive uses closed water cooling technology, and the main motor is sealed inside the top drive body, achieving a truly complete explosion-proof function.

If our products meet your current needs,Please leave us a message!

Product classification

Keywords

immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!